Lime treatment – unplanted drying beds – July 2019

- Organization : NGO Forum

Contact the author

Description of the treatment process

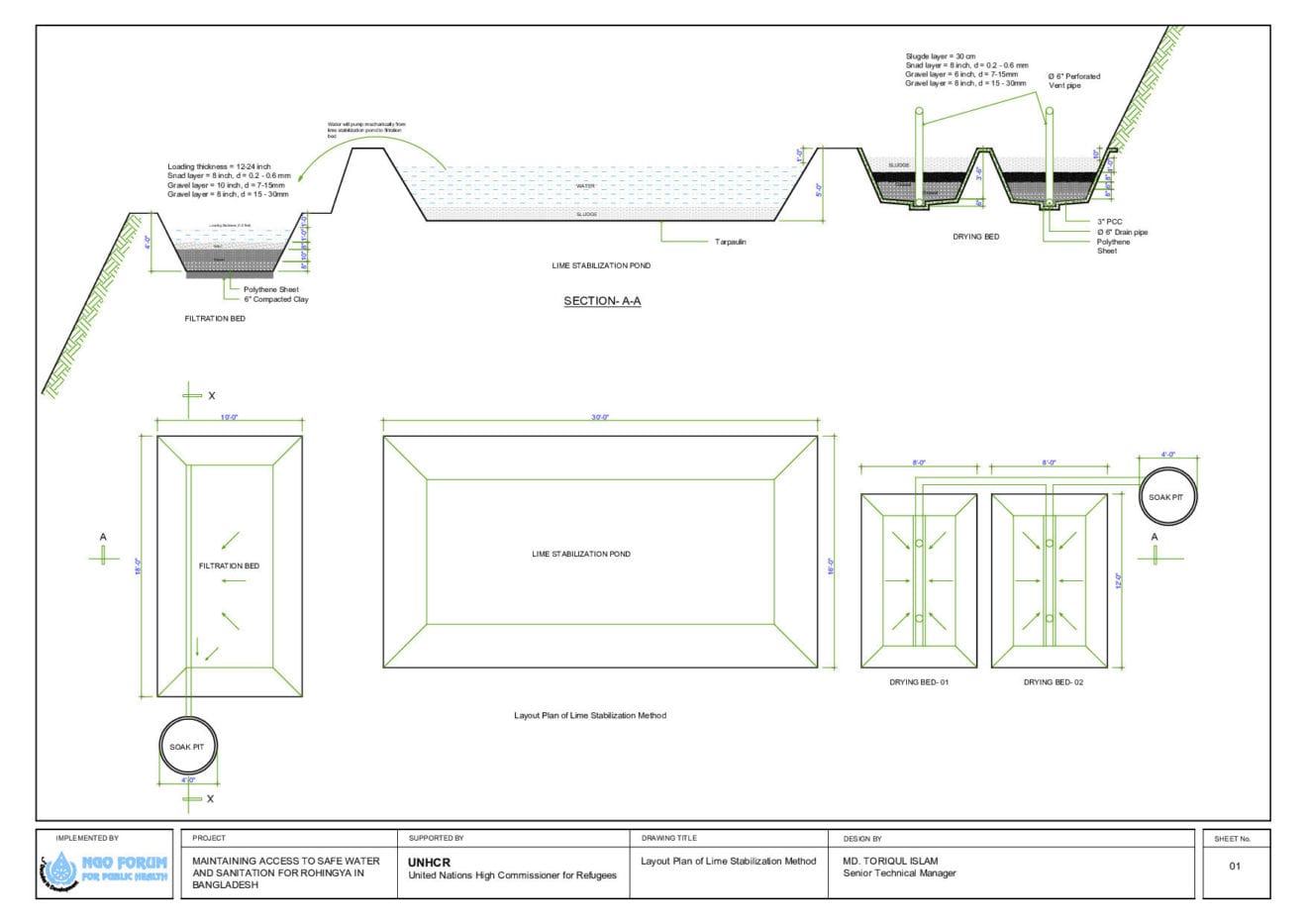

The Lime Stabilization method is a process where hydrated lime (also known as calcium hydroxide) is added and mixed manually by using simple mixing pump in pits. Addition of the hydrated lime elevates the pH that eventually kills the pathogens (disease causing micro-organism) and stabilizes the sewage, reducing odors and allowing further processing. Allowing the solids to settle in the bottom of the pit, the water can then be removed and spread over the ground area. Further, the remaining solids can be dried and be used to cover for landfill or decomposed to be used later as fertilizer.

Besides, there is a provision of filtration unit and drying bed using gravel and sand of different sizes. The separated liquid part (leachate) of raw FS pre-treated on drying beds further goes on a filtration chamber and is followed by a soak pit. A roof was constructed over the top of the drying bed to keep the sludge dry during the treatment process. The benefits of these beds include no requirement and use of power. The drying process is enhanced by evaporation and solid-liquid separation by gravity percolation of leachate. There is a scope of use dried sludge as soil conditioner. After the sludge has dried (around 15 days during the dry season) it is burned and buried.

Description of the emergency context

Living area of community: Kutupalong Camp Area in different locations

Local and international WaSH institutions with WaSH active role in the community: NGO Forum and other development organizations such as BRAC, ACF, PCCR, IFRC, Friendship etc.

Main waterborne diseases: Cholera, Diarrhea, Dysentery, Typhoid etc.

Indicators

Narrative

The terrain is a hilly region with ups and downs. NGOF considered the low lands beneath the hill for the construction of the fecal sludge treatment/disposal site, it is protected in such a way that people can’t see the sludge and it restricts the spreading of virus.

The details FS characterization of raw sludge was not undertaken during design.

The raw sludge is untreated non-stabilized sludge, which can be taken from pits and septic tanks.

Desludging of the pits is done using mechanical pump and the sludge is delivered to the processing site through hosepipes. Where the mechanical system is not suitable for transferring sludge from the pit to the treatment site, plastic tanks are used for sludge collection, operated with a manually run vehicle.

NGO Forum does the desludging through convenes pipe with the help of pumping. It maintains proper health safety such as: Mask, Hand Gloves, Gum Boot, Apron, Rake, Convenes Pipe, Octane running Pump, Generator, submersible pump.

The design was developed based on secondary information and data where the treatment performance of the lime stabilization technique was considered. The applied lime stabilization process includes hydrated lime (calcium hydroxide). When mixed with the sewage it raises the pH above 12, which kills the pathogens. Then the water is separated from the solids by sedimentation and pumped out with the inert water onto the surrounding land. In addition, there is a biological filtration of the effluent water from the lime stabilization pond. Further, the remaining solids are dried and burned to be used to cover landfill or to be decomposed. The capacity of the treatment plant is 35,000 liters per seven (7) days.

The lime stabilization and settlement pit general dimension has a length of 20 feet, width of 10 feet, height/depth of 5 feet and the overall volume of one pit is around 35 cubic meter. It is partially excavated up to a depth that is at least 1 foot above the water table. Following excavation, the overall height of the pit is raised to 5 feet through construction of embankment walls. Embankment walls have a slope of 1:2 (27°) in sandy soil, although the slope can be steeper if the soil has a higher clay content. The embankment is constructed of soil which will be compacted every 6”. The pit is lined with tarpaulin to prevent infiltration of untreated sludge into the ground. A roof was constructed over the top of the stabilization pond using tarpaulin to keep the sludge dry during the treatment process.

The construction was completed by an experienced external contractor. NGO Forum invited open tender for the proposed work. Then the vendor submitted quotation as per the provided quotation. The tender opening committee opened the tender box. The opening committee then submitted the quotation to the technical committee for the technical evaluation. After the technical evaluation, the technical committee submitted it to the purchase committee. Then the purchase committee did the financial evaluation based on the experience and financial responsiveness of the vendors. Finally, the work order was issued for the selected work.

The M & E of the construction and installation is emphasized throughout the implementation of FSM interventions to ensure the qualitative aspect of the technologies. A well-experienced and qualified technical team headed by the Technical Expert supervised and provided overall guidance to the Project Engineer and Assistant Project Engineer in relation to technical aspects. A major portion of the outputs are accomplished with the direct involvement of the NGOF technical team, having wide experience in drawing, designing, construction and installation of FSM infrastructures.

Access and legal permission are needed to take the materials.

NGO Forum uses an internal expert for any upgrading or decommission of the FSM, following the sector standard and guidelines. In a few cases NGO Forum has hired an external contractor.

Enough Water, local vehicles for transporting in the hilly area, a necessary community consultation as well as permission from the CIC and SMS are resources temporally needed for upgrade/decommissioning.

Mask, Hand Gloves, Gum Boot, Apron and Rake is used as PPE. NGO Forum normally follows the sector standard rules for using PPE. Every dislodging volunteer is responsible for completing the task. Over them, there is the Assistant Engineer and CHP for the monitoring. One of the challenge is that to ensure the quality, our Project Engineer has to supervise directly.

Desludging team is involved for the emptying and transportation of sludge. NGO Forum uses equipment like octane operated pump, convenes pipe, 2-inch PVC pipe, Hoss pipe, Shovels, mattocks, buckets, pH meter, bamboo stirring rod (for mixing lime in the pit), 2” dewatering pump, Jubilee/lock Clip, bucket, mask, hand gloves, gum boot, apron, rake and materials like alum, lime and bleaching powder.

The output sludge production in comparison to the sludge input flow is 0,1428 kg/m3.

The pH variation is 4,5.

Mask, hand gloves, gum boot, apron and rake are used as PPE. NGO Forum normally follows the standard rules for using PPE. Every dislodging volunteer is responsible for completing the task. Over them, there is an Assistant Engineer and Community Hygiene Promoter (CHP) for the monitoring. There are washing facilities available.

The site is protected by a fence and drainage is implemented.

It is indicated that the lime stabilization of sludge, by maintaining the pH at a level of 12 or above, is very effective for the removal of pathogenic viruses and bacteria. However, although lime stabilization can deactivate parasite eggs, it does not kill them. Treated sludge may therefore contain eggs that could later hatch into parasites (worms/helminths). Due to the potential risk from parasite eggs, the sludge needs to be buried. After the sludge has dried (around 15 days during the dry season) it is burned and buried.

Challenges:

Finding a site that maintains at least 25 meters away from any groundwater wells or natural channel may be a challenge. To ensure good Hydrated lime (calcium hydroxide) because of its variable quality in Bangladesh may also be a challenge. It is important to always monitor pH consistently for two hours following lime dosage. It is vital to only use hydrated lime w/ >90% Calcium Hydroxide and to never use lime powder.

Multiple pH meters with spare batteries and deionized water for calibration are critical items for quality control. Besides these, it is a challenge to maintain the retention period for the treatment.

Strengths

Safely managed faecal sludge with chemical & biological treatment technique and environmentally friendly.

There is scope to create the opportunity from this where community people are economically benefited.

Weaknesses

NC

Lessons learned

If we construct small sewerage boreholes and increase secondary transfer stations and safety tanks then the cost will be reduced.

Constructing small sewerage boreholes or transfer stations, it can reduce contacts between staff and sludge.

Ensuring community engagement and engaging skilled volunteer can guarantee the sustainability of the plant.

The risk of environmental contamination from burial of lime treated sludge is relatively low, since the bacteria and viruses in the sludge are destroyed during the treatment process, leaving only the helminth eggs which are relatively large and are efficiently removed through the physical filtration process in the soil. A burial site which is 6 inch above the water table can therefore be considered safe considering the risk. After burial, sludge should be covered with a 6-inch layer of soil.

Specific challenges:

• the emptying frequency is too high, as a result it is difficult to maintain the retention period

• leakage of convenes pipe

• quality of effluent water

• space in the camps is limited due to the number of people and the topography

• landslides in the rainy season

In this system, there is a possibility of health hazards, by damaging the skin and causing burns for those who are involved in this activity. Gloves were worn when handling lime. Gloves have been issued to workers who are handling sludge or chemicals (lime or chlorine) and Eye protection also have been issued to workers who are handling chemicals (lime or chlorine). Forum has mitigated this risk through proper use of PPE. Besides these, there is a provision of water containing vinegar for washing. If dry lime is spilled on the skin, then it has to be brushed away as much of the lime as possible before it causes burns.