Lime Stabilization – Unplanted drying beds – March 2019

- Organization : IFRC

Contact the author

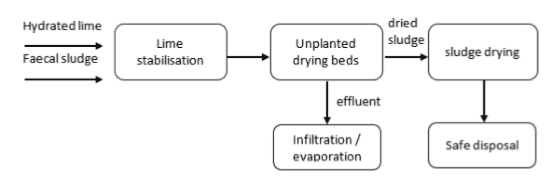

Description of the treatment process

The faecal sludge treatment site is designed with the primary objective of pathogen elimination. It consists of lime stabilisation for pathogen elimination, unplanted drying beds for solid liquid separation and dewatering and a sludge drying area.

Description of the emergency context

The FSM site is situated in a densely populated refugee camp (Cox’s Bazar, Kutupalong-Balukhali extension area, camp 18) with hilly terrain and poor path conditions.

Indicators

Narrative

On average 5m3 sludge is treated per day, which is in accordance with a target population of 10,000 people served with FSM activities and a sludge accumulation rate of 0.5 l/person/day.

Desludging and sludge treatment efforts seem to answer to the need in our 23 blocks (9,383 people). However the actual number of people reached is somewhat lower as all latrines constructed under supervision of Save the Children and Friendship are normally emptied by these respective organisations.

Other FSM actors state a two-week period between desludging, which calculates to a sludge accumulation rate of 2.9 l/cap/day (assuming full latrines, 0.8 m3, after two weeks).

The adddition of hydrated lime (Ca(OH)2) to faecal sludge increases pH and results in pathogen inactivation and limited sludge stabilization [1]. Different combinations of pH and exposure times result pathogen removal, field research has shown that faecal sludge from pit latrines treated at pH > 11.5 for a period of 2 hours meets WHO standards [2].

Loading rate 5 m3/day assumption: 0.5 l/person/day, 10,000 people

Lime dosage rate 20 kg/m3 sludge typical range: 1 – 17 kg/m3 faecal sludge

Lime consumption 100 kg/day actual lime use 110 kg/day

Before desludging a 1:1 lime-water mixture is added to the barrels. Once the barrel is carried back to the site the content is stirred for approximately one minute followed by pH measurement.

The unplanted drying beds are designed for a hydraulic loading rate of 30 cm/m2 and a solid loading rate of 200 kg TS/m2/year [1; 3]. The unlined beds (5×2 metres) are filled with coarse gravel topped with sand and a permeable sand bag cover to allow for easy removal of the dried sludge and to avoid sand removal during bed emptying.

Loading rate 5 m3/day assumption: 10,000 people, 0.5 l/person/day

Hydraulic loading rate 30 cm/m2 typical range: 25 – 30 cm/m2 [1]

Solid loading rate 150 kg TS/m2/year typical range: 100 – 200 kg TS/m2/year [3]

Drying time 7 days assumption: 1% total solids concentration

Drying area required 100 m2 0.01 m2 / person equivalent

Lime stabilisation is a simple and robust technology that can be designed, constructed and operated in the local context. Design is straightforward and can be done by a WaSH officer. Construction and operation and maintenance do not require prior knowledge and experience.

The site has been reinforced and is protected against flooding.

The key component hydrated lime is a common building material and can be purchased locally. Other materials such as gravel, sand and building material will also be readily available. Lime stabilisation is particularly suitable for the relief and recovery phase in the humanitarian context.

The area required for the FSM site is roughly 600 m2 (0.06m2/person). This includes all facility buildings, office and warehouse and ample free space but excludes the area needed for safe sludge disposal. An area of only 140 m2 is directly occupied by drying beds. Guidelines developed by USAID for lime stabilisation of septage in the Philippines state a land use of 400 square meters for a daily flow of 5 cublic meters per day [6]. The current FSM site has a spacious lay-out and part of the land is left undeveloped, the total area is estimated at 2,000 m2.

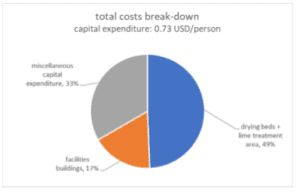

Costs for construction of the FSM site are estimated at 0.73 USD/person (or 6,500 USD). Construction costs include site preparation and construction of all facility buildings, with the exception of the office and warehouse building. Transport and labour costs are included and estimated at 10% and 30% of material costs. Programme costs are not taken into account.

The FSM site will be upgraded in line with the WASH sector strategy on faecal sludge management.

It is a simple and robust technology that is transferable to site workers.

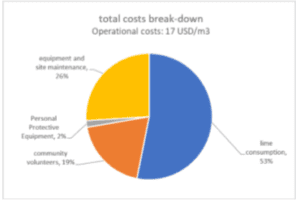

Daily operation and maintenance costs of the FSM site are estimated at 17 USD/m3. This is in line with the costs of 12m3/USD based on chemical use only, as estimated in the emergency sanitation project [5].

Half of the operational costs consists of hydrated lime usage. Equipment and site maintenance, such as the purchase of washing consumables, pH meters and bamboo, are a quarter of operational costs. One fith of the costs consists of monetary incentives for community volunteers. Personal Protective Equipment, although of high importance, is only a small fraction of the running costs.

The site can be reached on foot and is inaccessible for any type of motorised transport (tricycle, small truck, pick-up, vacuum truck) and non-motorized transport (bike, cart). Long rainfall periods during the monsoon and cyclone season worsened path conditions in the camp and desludging and sludge treatment had to be stopped.

There is safe disposal of 0.5 m3 dried sludge per day.

Strengths

The main benefits of chemical treatment in emergency settings is the robustness and control of the full process, the relatively short start-up time and operation throughout the rainy season.

Design simple design, can be done by a WaSH officer

Construction easily available material, Local artisans can construct the FSM site

Operation and maintenance staff can be easily trained to operate and maintain FSM site

Main strenghts:

– Kill pathogens

– Simple and robust technology that is transferable to site workers

– No energy requirement

– Short start-up time

– Modular system, easy to scale up

Weaknesses

NC

Lessons learned

Reduce liquid content prior to discharge at treatment to avoid transport of liquids and frequent emptying, ensure latrine design allows for manual desludging, increase desludging capacity and design low-tech treatment options with quick start-up time and ensure pathogen kill that also is modular for future purposes (up-scale, climate modification etc.).

Desludging and transport is coordinated with available treatment capacity, but it was a bottleneck during dry season when drying capacity is fast.

Faecal sludge treatment is never better than the latrine design component, desludging capacity or transport situation. With change in climate, latrines could be flooded, infiltration will reverse, transport and access might be reduced or impossible. During rainy season the treated faecal sludge volume could stay fixed, but people served decrease since liquid content possibly increase. Once again, faecal sludge is a complex process well integrated and dependent on the full faecal sludge chain.

The treatment facility will never perform better than the weakest link in the faecal sludge chain.

– Large scale mixing of dissolved lime and faecal sludge can be a challenge since sufficient mixing is crucial for an efficient pH increase. When receiving larger volume of faecal sludge the logistics of handling 50 barrels might be more tricky than finding a way for large scale mixing of lime.

– Lime and alum works as coagulant and improve settling properties. When applied at large scale in a 1000 litre overnight (attempt to a settling tank), the challenge were to discharge the solids and liquids separate without short circuiting and mix-up solids and liquids again. Idea is to discharge liquids first prior to solids, just need to address increase in viscosity of solids without the hydraulic head from liquids on top. Settling requires screening to prevent blockages, and liquids should be decanted from the top of the tank first to prevent short circuiting. This can be achieved using a flexible hose that is connected to an outlet at the bottom of the tank. The hose can be lowered into the liquid layer where it can drain down the hose and out to a soakaway.

– Infiltration beds with gravel as only filter media clogs rapidly of the solids.

– Drying time will fluctuate with changes in climate.

– Local sandbags work on small scale for solid liquid separation. To try on large scale.

– Local rice bags were to compact to allow rapid infiltration on large scale, drying bed ponded.

– Measurements days after discharge to drying beds show pH 12.

– Regardless of what technology is employed, a treatment site is ultimately a sludge factory. Therefore safe and sustainable disposal routes need to be further development and investigated (i.e. appropriate fertilizer use in surrounding agricultural areas should be researched and markets developed).

Thank you for sharing this helpful post with us.